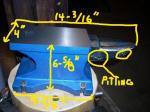

First, the downside. This anvil arrived with a horrible, sticky/tacky baby blue attempt at powdercoating on a pebble-textured finish that covered every part of the anvil except the face. Even the horn - which needs to be smooth - had this pebbled finish and sticky "powdercoat" which came off readily any time it wasa touched. On the horn, there were a few small voids under this crappy finish. My only other complaints are that the hardy hole is not exactly square - I have to round the corners on any hardy tools I want to use, and the Pritchell hole is poorly placed.The upside - a few hours of careful work with an angle grinder and flap disc had the anvil cleaned up nicely - and as mentioned before, the face was nice and smooth from the start. I used the grinder to smooth the sides and the horn (including some minor reshaping and getting rid of multiple tiny voids), then sprayed Loctite rust inhibitor on the non-work surfaces of the anvil, leaving the newly polished horn and the face bare steel. After a bit of custom paint and mounting it to a stand made of 4x4s with steel brackets and 6" lag bolts, it was good to go. It has needed no further work, and has given me over a year of solid, reliable performance.One last thing - before I mounted it to its stand, the anvil had a piercing, loud ring when struck. Bolting it down securely has cut the ring to a huge degree, and it's no longer an issue.